Sheet Metal Cone Manufacturing

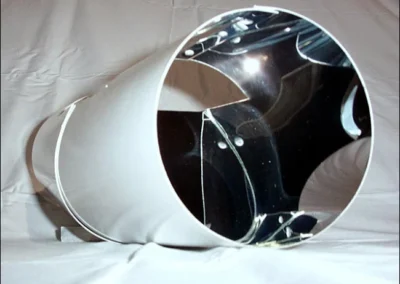

Metal cone manufacturing is the process of creating cones from flat sheets of metal. Manufacturers use different methods depending on the size, shape, and material of the cone.

Rolling is the most common process. This involves using a rolling machine to form the cone. A metal sheet is fed through a set of rollers that are shaped to create the desired cone profile. Rolling is a good option for small to medium cones made from thin sheet metal.

Spinning is another popular method that utilizes a spinning lathe to form the cone. A piece of metal sheet is placed on a rotating mandrel and a spinning tool is used to press the sheet into the desired shape. Spinning is a good option for larger-sized cones made from thick sheet metal.

Metal cone manufacturers create cones for a wide variety of industries, including construction, automotive, aerospace, and food and beverage. These can be used in applications ranging from structural components, hoppers, and fuel tanks to decorative architecture elements.

To Get A Quote on your Project’s Needs: Call 866.276.6242 or Request a Quote.