Blog

Risk Mitigation in an Age of COVID-19

EXECUTIVE SUMMARY This Blog will discuss some of the most important factors to consider when performing a cost benefit analysis of your supply chain as it applies to overseas manufactured components in your company’s lighting products. The paper will discuss the...

10 Reasons to Choose Reflective Concepts for Prototyping

All of our prototype reflector components and assemblies are tailored to your specifications. You can bring us anything—drawings, sketches, CAD data, or a concept description—and our engineers will turn it into a cost-effective reality. If you’re considering several...

Grocery Shoppers Impacted by Lighting

A grocery store can send you into sensory overload. There’s vibrant fruits, vegetables and fresh-cut flowers upon entering; the irresistible aroma of warm bakery bread wafting through the air; and, relaxing music persuading you to stroll down all the aisles. Why?...

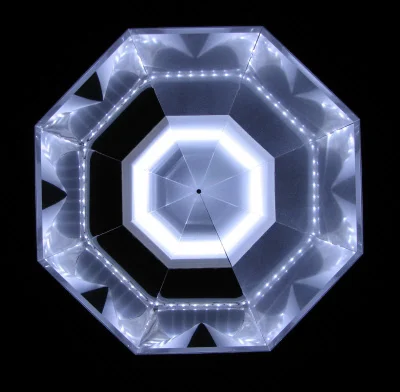

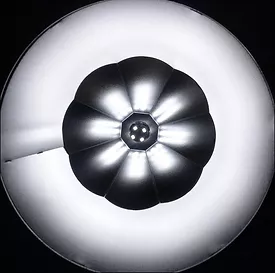

Top 5 Reasons to use Tailored Reflectors

Tailored reflectors provide product development engineers with a number of value added advantages for successful project completion. 1. Tailored reflectors meet photometric and aesthetic requirements. Our tailored reflectors are designed to accommodate the wide range...

Rapid Prototyping Quick Guide

When it comes to the production and profitability of fabricated reflective optics, time is of the essence. But, a quick turnaround should never leave you questioning precision or quality.